Machine Guided Mine Drilling

With the move from underground to open pit mining, South Africa's Landau Colliery sought to increase safety, accuracy and productivity with the help of machine guidance drilling systems.Published: January 2015

Author: Trimble Heavy Construction Division

Introduction

Situated just outside the mining community of Witbank, Mpumalanga, South Africa, Anglo American's Landau Colliery covers 8,200 hectares, producing between four and five million metric tonnes of high-grade export coal annually, and about one million tonnes for local consumption within the power sector.

Initially established as an underground mine in the 1960s, the operation moved to open-cast in the 1990s.

Open Cast Challenges

By moving from an underground to an open cast operation, a number of challenges emerged.

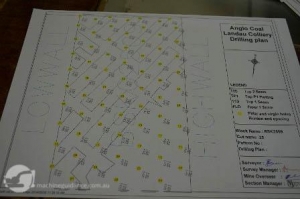

In open cast mining, after stripping the top soil away, the hard overburden needs to be drilled and blasted and then removed with a dragline, to expose the coal seam. The blasted material must then be correctly fragmented to ensure suitable conditions for the dragline in which to operate - namely, a soft digging environment. The better fragmented the overburden, the better the excavator is able to operate in clearing the site. The drilling operation therefore, plays an integral part as drill patterns need to be planned to ensure that the overburden is fragmented correctly, timeously, accurately - and safely.

Traditionally, to design a drill pattern/grid, surveyors were sent into the field to stake out the area as determined by geological surveys. The surveyor's job was to put 'markers' in place, indicating the drill position. However, there was no way to determine the depth of physical ground underfoot, which ranged from a few centimetres to several metres, determined by prior underground mining operations. Thus, the previously undermined ground became unstable and often treacherous with unpredictable sinkholes occurring, resulting in injuries and even fatalities, threatening the safety of both men and machines.

With the ever increasing quest to reduce production costs and increase the safety of its mining operation, Landau Colliery sought innovation and efficiency as a solution. The criteria were threefold, focusing on improving the safety, accuracy and productivity of the drilling and piling operation.

3

4

After investigating options for a system that answered all the above required criteria, the Trimble DPS900 Drilling and Piling System was chosen, as it offered the total solution. The system was installed on two drill-rigs that have been deployed on-site.

The operator is able to monitor the rig as it moves from drill hole-to-drill hole, while the on-board monitor (top-mounted dislay in the adjacent photo) ensures accuracy of drilling, through simply setting the drill mast to accommodate the pitch and roll of the rig.

The in-cab Trimble Site Tablet, (bottom-mounted display in the adjacent photo) is a rugged and fully connected field computer for measuring and site positioning, allowing operators to see blind spots and avoidance zones.

The Trimble GNSS Base Station and TDL 450L radio, housed at the office, ensures accurate and reliable communication from the office to the field. Positioned at the highest point above the office building, on an old guard tower, the base station receives satellite information and then broadcasts the corrected signal via the connected radio to the drill-rigs and surveyors on site.

With the two GNSS antennae mounted on either side of the drill-rig, the drill guidance system positions and orientates the machine according to the information received from the base station, trimming the rig to accuracies within five centimetres of the drill-hole centre point. The DPS900 system includes a depth-sensor which records the accurate drilling which can then be checked against the geological model.

Machine Guidance Benefits

Machine Guidance Benefits

Safety

According to a mine spokesperson, the idea to use the machine guidance system was to "eliminate the risk to man and machine, which the system achieved in numerous ways."

With the drill patterns uploaded to the cab of the machine, the drill operator navigates the rig to the required positions from any direction, as he no longer requires physical markers and surveyors are no longer forced to walk on dangerous, unstable ground while staking the drill pattern. The environment and site is viewed on the in-cab tablet, allowing operators to see blind-spots through camera views around the machine, and the operator is no longer forced to sometimes stand up in the cab to visually gauge where exactly to position the drill.

In addition, audio-visual warnings alert the operator to avoidance zones when working in areas in which they shouldn't be. Compact and ergonomically positioned, with simple instrument control, the Trimble DPS900's clear, easy-to-read on-screen graphical interface ensures that the operator is in constant control of the operation, from the safe confines of the drill-rig.

Greater Accuracy

GPS guidance directs the operator to position the drill to within five-centimetre's tolerance of the centre point of the specified drill co-ordinates, where previously, accuracy was within 50 centimetres. Through the on-board software, the drilling information is downloaded post-drilling and the as-drilled information is compared with what was anticipated in the design - by way of depth and spacing of drill holes. Mines are thus able to accurately fragment the overburden when they blast.

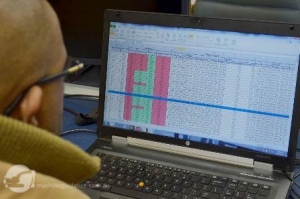

Via tailored reporting, information is downloaded post-drilling. Data is compared with anticipated production against actual production, with reported improvements up from mid-80 percent to within the high-90s. From the office laptop, the Survey Manager is able to monitor the progress of the drilling operation via the internet feed from the rig.

According to the spokesman, prior to using the Trimble DPS900 system, drilling accuracy was substantially less as, despite the holes being accurately staked through manual methods, the entire process of marking, removing the markers, drilling and assessing the results, was not only time consuming, dangerous and labour intensive, but also came with an increased chance of human error. For example, inadvertently a marker could be repositioned when a vehicle moved over or passed by it, compromising the accuracy of the drilling operation.

Landau Colliery believes that the system's accuracy has clearly shown discrepancies in the previous method used, between the geologist's model and the reality of what is actually achieved in the drill patterns. The DPS900 system offers consistency of drill depth and predictability of output on site and prevents costly rework.

Before using the GPS system, there were times that when results were compared between what was planned with what was achieved, the statistics did not correlate, as there was a significant dependence on 'visual' accuracy. According to the mine, the current accuracy drilling is above 90 percent, up from within the 80s.

Operational Cost Saving

The machine guidance system has benefitted the mine through improving operational time and thus costs. For example, where before a surveyor had to physically stake a drill hole previously, this is removed through GPS navigation and personnel can be redeployed in other areas and operations. With the drill pattern loaded onto the in cab Site Tablet, navigation from one hole to the next is faster as the need to manually gauge and visually manoeuvre and position the rig is eliminated. The GPS ensures accurate trimming of the rig between holes, through auto-select: the system points the machine accurately, regardless of drill inclination or elevation. This in turn, reduces rework as well as over and under-drilling.

Also, multiple drill patterns can be uploaded onto the system at once, which means that when a section is complete, there is no downtime waiting for a surveyor to be called out to stake out a new area while the rig is standing idle; the next drill pattern can immediately be accessed and work can continue uninterrupted, even after-hours - during weekends for example.

With tailored reports - generated as frequently as desired - the entire operation no longer relies on manual recording, where previously, operators and surveyors entered information individually. Historically, the operators had to write down their drill depths, and the longer the hours they worked, the greater possibility for error to occur, owing to fatigue.

One of the mine's Section Surveyors explains that by doing away with the manual process of recording drill holes, the drilling process has not only been speeded up, but is more accurate, as the system records everything electronically, reducing human error, where beforehand, not necessarily all holes were actually drilled, despite being plotted on the drill pattern. With the machine guidance, the information is recorded, logged and controlled electronically and accurately, thus eliminating human error, saving time and money.

Training to use the DPS900 takes a matter of days and everyone involved is more than satisfied with the outcomes.

Conclusion

Operators on the mine say that the machine guidance has been of great assistance and they are doing much more accurate work in a less dangerous environment and the system alleviates fatigue on the job while quality is retained. The system has helped operators to use the drilling machine faster, making it easier to move from hole to hole and the display on the Site Tablet shows exactly where the drill holes are making it safer to drill.

Landau Colliery assures that plans are afoot to install the Trimble DPS900 systems on other drilling machines on the mine in the not too distant future.

Credit Source

Trimble applies technology to make field and mobile workers in businesses and government significantly more productive. Solutions are focused on applications requiring position or location-including surveying, construction, agriculture, fleet and asset management, public safety and mapping. Read more about Trimble Heavy Construction at www.trimble-productivity.com.

Return to Articles