Engineering Survey Data - Data Modelling & Management

This article highlights the importance of survey data modelling and survey data management for construction projects. Accurate survey data is crucial for the efficiency of any construction project, particularly those that uses machine guided construction methods.

Published: 22nd August 2012

Author: MachineGuidance.com.au

Introduction

The following article highlights the importance of both survey data modelling as well as survey data management for construction projects. Good survey data and in particular survey data modelling forms the backbone of an efficient construction project. Without a completed survey design model a project can quickly become inefficient and unprofitable.

Similarly, managing the survey data on large construction sites is equally important and should be carefully considered when establishing a jobsite. Survey data management should guarantee consistency amongst all survey devices, data accountability, reliability of designs and should also ensure an efficient survey field process. This includes managing survey data on machine guidance systems as well as supervisor and engineer survey kits.

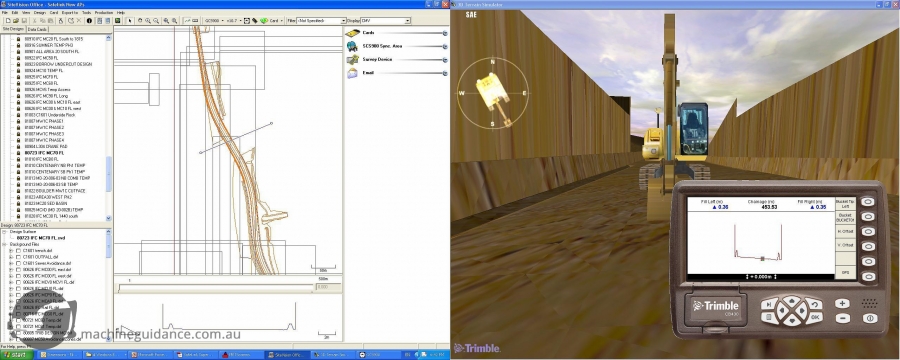

Image - SVO Simulation

Survey Data Modelling

Survey data modelling refers to the creation of a computer-generated three-dimensional surface that is produced to represent the intended construction design. Survey models are used in all survey-related office and field devices. Survey modelling differs from design modelling in its level of detail. Design models are sometimes quickly created to gain an overview for a specific purpose while they may serve as the starting point of a survey model they usually require modifications and further input before being construction ready. When provided with design models, the surveyor must compile them together and check them for consistency. Survey models also need to be referenced against paper design data (construction drawings).

Used correctly, survey data models can electronically build a construction project in the office before turning any soil on-site. While it is a time-consuming process, if the modelling is completed before the construction phase of the project begins then potential problems can be identified and rectified without the need for double-handling of material or wasting of any diesel. Issues of design construct-ability can also be identified at this stage allowing them to be queried and corrected reducing any delays in the construction works.

Survey Data Modelling (2)

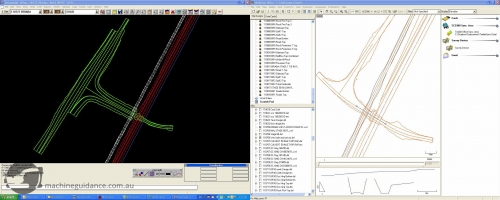

The survey data modelling process involves numerous steps that should be completed prior to construction. The model is digitised by following the earthworks and pavement design plans. This will allow the calculation of the total earthworks volumes model as well as ongoing monthly volumes to complete.

The next step of survey data modelling is to digitise the drainage details to ensure that all drainage structures fit with the earthworks design. This includes the checking of such things as culvert headwalls against earthworks batters, inlet drain locations, etc. Structures drawings are usually digitised last (they are often the last drawings available) and then compiled with the master survey model. All digitising is constantly checked against each other both for construction consistency as well as an independent check on the accuracy of the survey data.

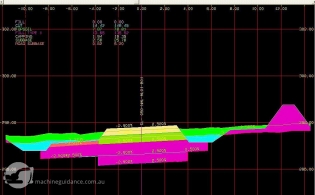

During this modelling process, a detailed topographical survey of the project will also be required to determine the design intersection points and best model fit, along with updating existing surface models to finalise volume computations. Similarly, geological testing may be required in order to determine the sub-surface strata.

Generally speaking, the sub-surface material will consist of a layer of organic material that is unsuitable for earthworks fill, a layer of softer material that may be suitable for scraper fleet hauls, a layer of rippable rock that will require heavier plant such as bulldozers, followed lastly by a layer of hard rock that will require a drill and blast operation if the material is to be utilised. Once the existing surface has been accurately surveyed and the sub-surface layer depths identified, then the survey data model can be used to make mass-haul determinations and assist in construction works programming.

Survey Data Modelling (3)

Completed survey data models are especially important in today's construction environment where traditional survey setout is being replaced with machine guided construction. Where as traditional survey setout provides a design guide every pegged cross-section (usually at 10m or 20m intervals), machine control technologies use the digital survey model to access design information for every millimetre of the project. This means that any design model inconsistencies or errors will be loaded not only into survey devices, but also directly into the machines that are responsible for building the project.

Supervisors are also given immediate and full access to the design models through the use of vehicle-mounted and mobile survey devices. The ability to take full advantage of all this equipment and particularly the machine control plant is largely dependent on an accurate survey model.

Therefore, accurate design modelling should be performed at the earliest possible stage of a construction project and ideally be completed prior to the construction phase. Thoroughly analysing and preparing digital survey data early will ensure an efficient and effective jobsite with minimal design model amendments which in turn will reduce project timelines and increase profitability.

Survey Data Management

Along with completed survey modelling data, it is also important to employ the use of a good survey data management system. Design changes that occur mid construction are often inevitable and it is important to utilise an efficient process of managing data updates.

Similarly incoming survey field data needs to be managed in an efficient manner. Having an effective data management process is crucial to ensuring survey data that is consistent, accountable, reliable and allows for efficient field operations. This is particularly true on larger construction projects that employ the use of multiple survey crews.

Data Consistency

Data Consistency

The most important element of a survey data management system is providing consistency. The system should ensure that all survey devices are equipped with the same information. The system needs to guarantee that the latest design revisions are in use throughout the survey department and that all superseded designs are eliminated from field use. This process will make certain that there are no design file conflicts amongst survey devices.

Data Consistency (2)

Any design changes should be made centrally and then synchronised across all field devices in order to guarantee consistency. Rather than keeping data in isolated, individual files, the master survey files should be stored in a central location and then the data should be distributed to all devices. This will allow easy access to information as well as guaranteeing that all survey crews have access to the same data set, eliminating miscommunications and conflicts.

A similar process should be employed with the use of field data. Data collected in the field should be synchronised within the system, processed at one source and then removed from the field device. Field data should be integrated into the office-based system in a way that provides open access so as to eliminate double-handling.

Not only is data consistency important amongst all survey devices, but it is also important to maintain consistency across other users of survey information. This includes machine control systems as well as foreman and engineer devices.

Data Accountability

Data Accountability

A survey data management system should ensure data accountability. We've all seen it - when something goes wrong it's always someone else's fault! Discovering the source (and subsequently the solution) of a survey error can be a difficult process when everyone has the ability to manipulate data individually.

By centralising the design creation and any design amendments, the result is an increase of accountability. Having one person responsible for the design means that when there is a question over the design, there is one person that is able to assist in answering / solving the query. Similarly, having someone accountable for the data means that it is easier for incoming information to be received and disseminated throughout the survey department. It also means that when something goes wrong, the responsible person cannot hide and you will know exactly which desk to walk up to!

Data Reliability

Data Reliability

Another feature of an effective data management system is data reliability. Because the system ensures an accountable person, more care is taken when creating and checking the design data set. This includes flow on effects from changing one element of a design and assists the process of guaranteeing that all the separate design elements match each other.

A good data management system should facilitate a process whereby the data is received, processed, checked and distributed in a reliable manner. All survey devices should receive the same information through a synchronisation process or similar. This allows for a more reliable and clearer path for getting data from the office to the field.

Efficient Field Operations

Efficient Field Operations

A survey data management system should facilitate efficient survey operations in the field. If the design is managed efficiently in the office and then distributed to the field, then there will be no need to waste any survey or operational time by manipulating the design on-site.

This process fits with the emerging trend to use survey assistants for field works personnel that perhaps do not have the adequate knowledge or experience to adjust design elements. By adhering to this process, field surveyors begin to understand the field requirements of a design file (both from a survey and construction point of view) which will assist them in their future aspirations of creating design models.

Having a good data management process will minimise field operation downtime as their will be no need to manipulate elements of the design. Managing survey data will also assist field operation efficiency as there will be no need to attempt to work out what design changes a previous surveyor performed at an earlier stage of the construction process.

Spare 2

Example of Survey Data Management

Let us explore an example of a simple yet typical survey operation of setting out a culvert including pipes, blinding and headwall.

v

Poor Survey Management

In our example, an on-site surveyor discovers that the as-constructed pipe length differs from the design. Upon setting out the headwall blinding, the on-site surveyor adjusts the design in his field survey device to suit the new pipe length. The blinding is constructed to the field set-out.

Let us know imagine that this original surveyor is away on R&R break and not available for the next construction phase which is building the culvert headwall. The construction crew request survey setout to place the headwall formwork and a new field surveyor is tasked with the setout.

Because the original surveyor's adjusted design was performed in a field device, it is not available to the new surveyor. Because the culvert is on a large site with multiple survey crews, it is going to be difficult to find the person accountable for the change, making it difficult to discover the reasoning and solution behind the new design changes. Because the original on-site surveyor was purely looking at matching the culvert headwall and the pipe lengths, the approaching inlet drain is also not matching the new culvert headwall location and the earthworks batters above the headwall need to be re-worked.

The culvert crew are now waiting and watching as the new field surveyor attempts to reverse-engineer and re-design the headwall in the field to suit the pipe and blinding construction.

Good Survey Management

Good Survey Management

A more efficient way of managing this change would be for the original field surveyor to collect the as-constructed pipe length information and return the field data to the office. The field data would then be synchronised with the system and the accountable person notified.

The office surveyor would then be responsible for adjusting the culvert design to suit the constructed pipe length and then checking these adjustments against all the adjoining design elements such as inlet drains and earthworks batters. This process may be in conjunction with other members of the project team such as designers, engineers and foreman.

Once satisfied with the amendments, the office surveyor could re-issue the corrected design(s) and synchronise this data across all survey crews, ensuring that the design data is consistent across all devices.

When the field party returns to setout the remaining culvert features, there will be no downtime and no need to manipulate the design in the field. They will also have total confidence that the new design will match all surrounding elements of the project.

Conclusion

Construction projects and survey departments in particular should consider the importance of establishing good survey data modelling and survey data management processes. Completed survey data modelling should be performed at an early stage of the project prior to construction to ensure that all design models are accurate and build-able before wasting valuable field resources.

Consideration should also be given to how survey data is going to be managed in a consistent, accountable and reliable way that will allow for efficient survey field operations. Utilising an efficient data management system will allow the contractor to realise the full efficiencies of their survey personnel and equipment.

Return to Articles